Cross-hole sonic logging

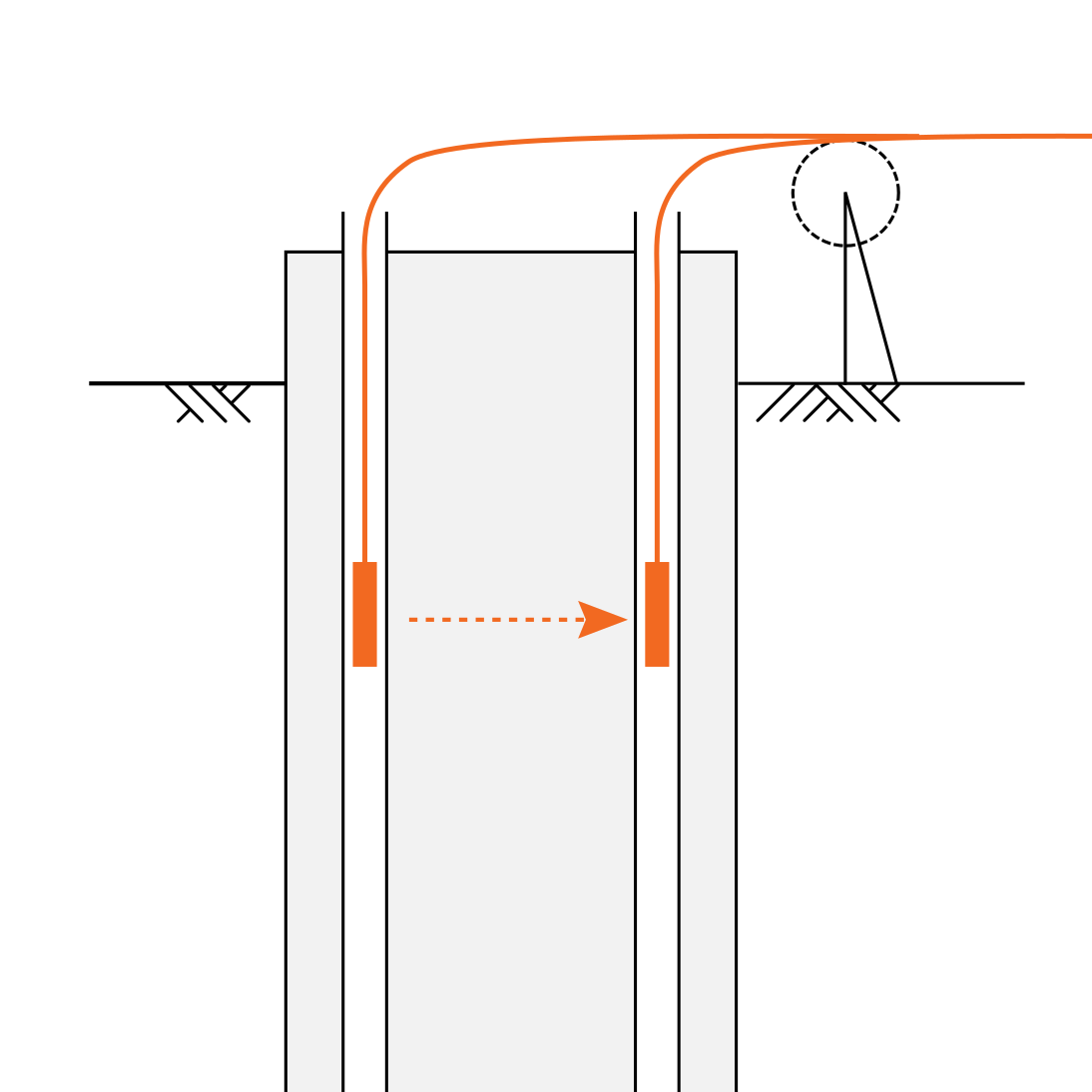

Cross-hole sonic logging is performed on deep foundations (such as bored piles or barrettes) or diaphragm walls (slurry walls). In order to perform the test, the element to be tested must have steel preinstalled reservation tubes, which are fastened to the reinforcement cage.

The test objective is to assess concrete quality between each couple of tubes.

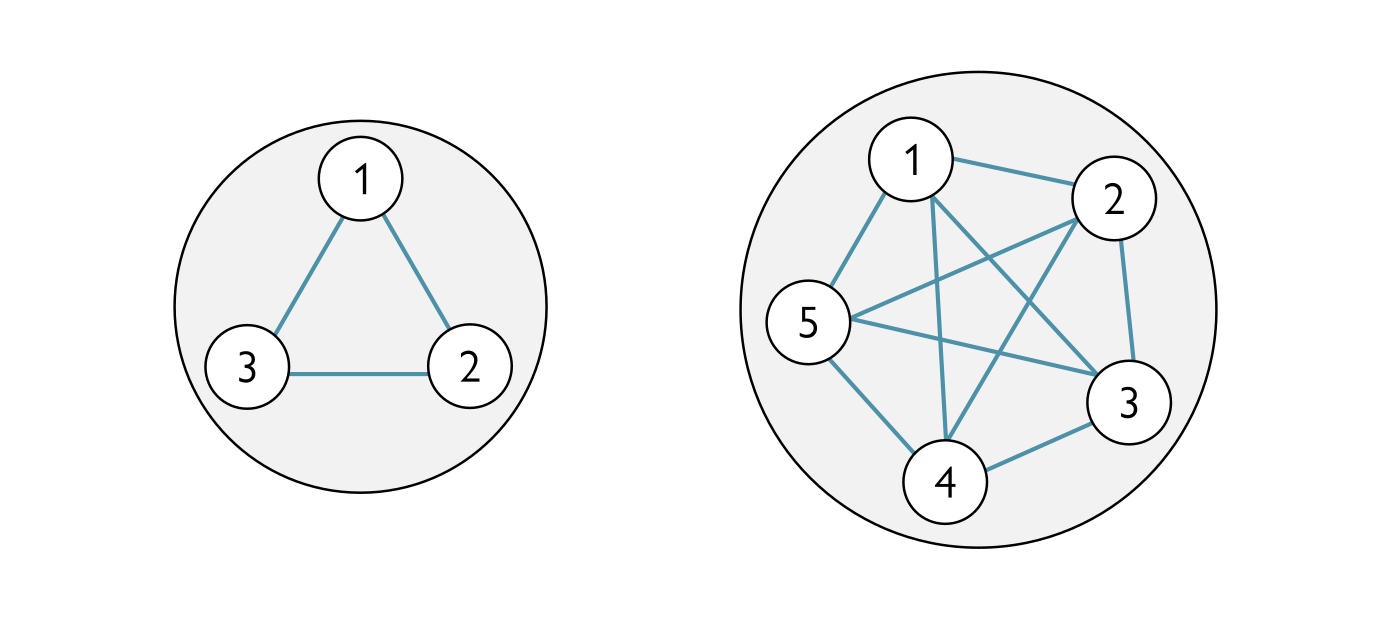

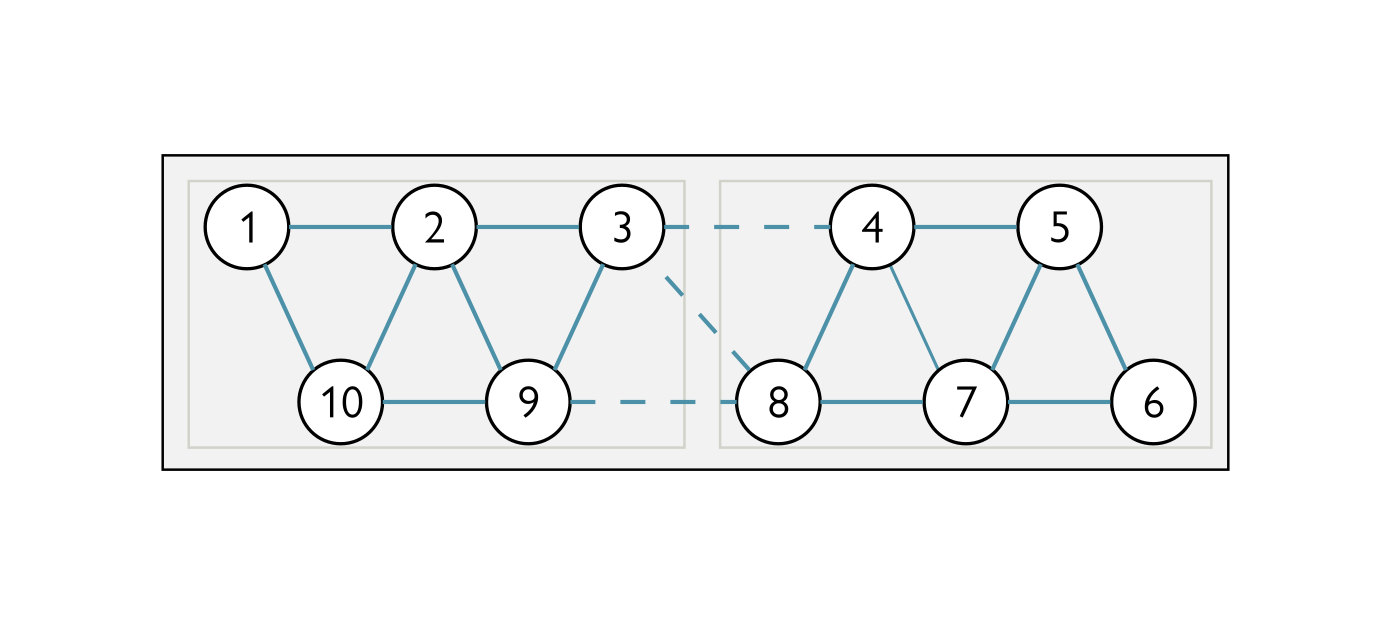

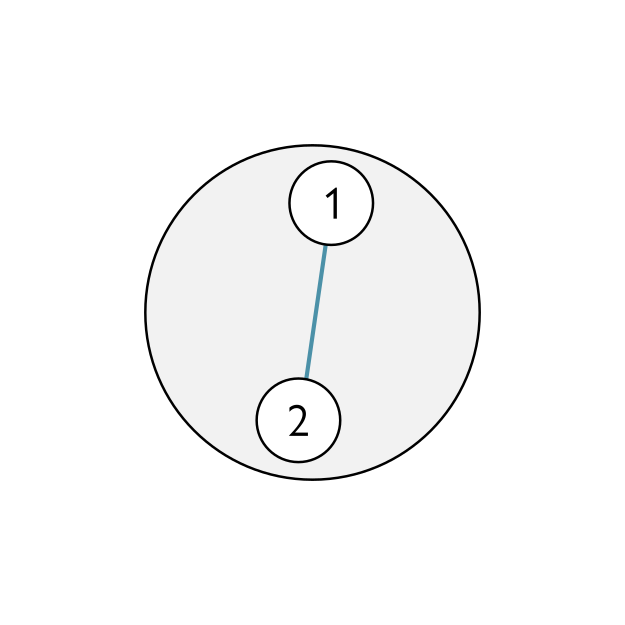

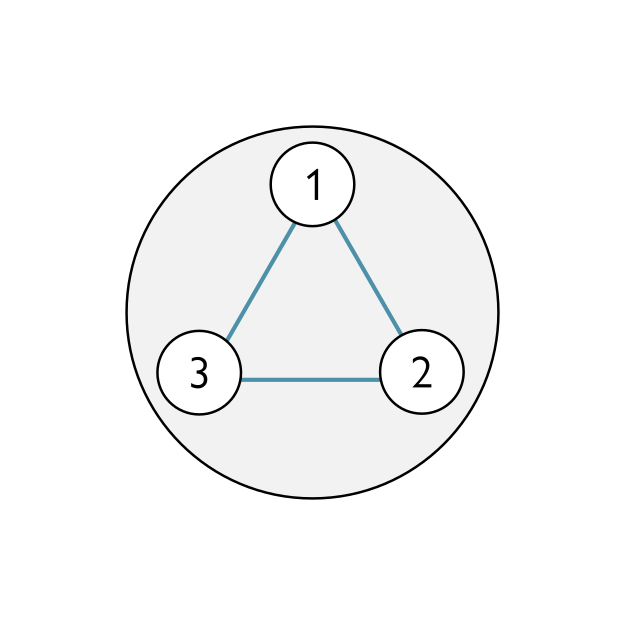

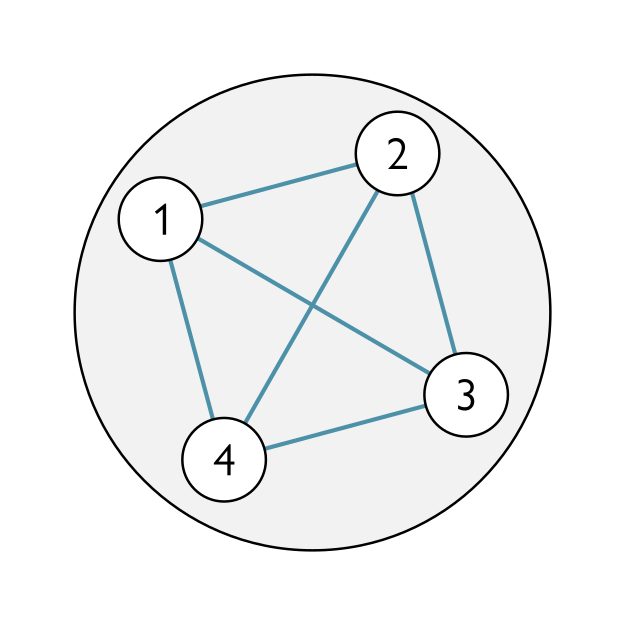

Hereunder are typical plan views of the reservation tube arrangements for various elements:

Test within a pile; here are two examples, one pile with 3 tubes (3 paths) and the other with 5 tubes (10 paths).

Test within a wall or a barrette; here is an example with 10 tubes (17 paths).

Once concrete of the element to be tested is 7 days old, the cross-hole sonic logging can take place.

First, two ultrasonic probes, one transmitter and one receiver, are lowered to the bottom of two adjacent tubes which are filled with clean water. The transmitter probe is capable of emitting an ultrasonic pulse while the receiver probe is capable of receiving the compression P wave resulting from the pulse.

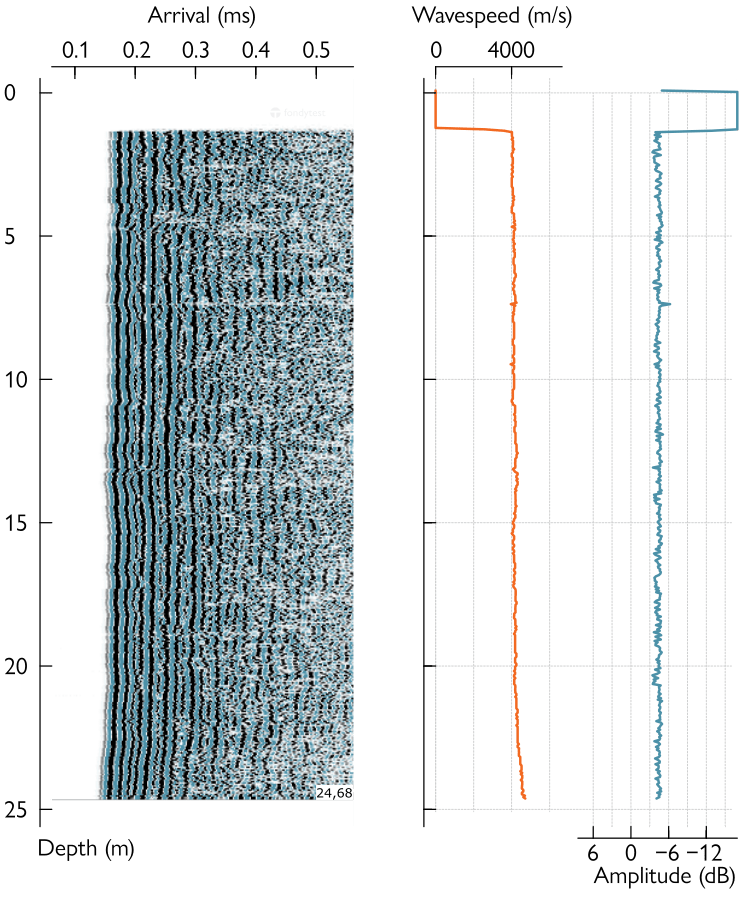

Both probes are then pulled up simultaneously, in order to be on the same horizontal plane, while measurements are taken at regular intervals. Succession of all the measured signals yield a profile versus depth between two tubes, as depicted hereafter.

The measurement is repeated for each couple of tube.

The main advantages of the cross-hole sonic logging test are:

-

Interpretation is relatively simple

-

Cross-hole sonic logging is not limited by L/D ratio

L and D are respectively the length and the smallest transversal dimension of the tested element.

-

Cross-hole sonic logging is only limited by the length of the cables attached to the probes

-

Cross-hole sonic logging is well-suited to control the concrete quality inside the reinforcement cage, by depth and by quadrant

-

Installing reservation tubes incites the contractor to better casting

The reservations tubes implies a possibility of testing – even if all the elements are not tested after all.

Cross-hole sonic logging main limitations are:

-

The test assesses the concrete quality only between the tubes

As a result, concrete quality issues outside the tubes paths cannot be detected.

-

Small horizontal cracks are unlikely to be detected

-

If a reinforcing bar blocks the path between two tubes, very little information can be deduced from the test

-

A small defect near the tube can appear large

-

Reservation tubes have to be installed before casting and grouted after testing

-

Debonding and bleeding are easily interpreted as issues

-

At least 7 days are needed after casting to allow the concrete to cure

-

The test cannot give information on the contact between the element toe and the underlying stratum

Only if the reservation tubes are prolonged below the toe can the test give information about the contact.

For questions, remarks, or a quotation, please do get in touch with us.

We perform cross-hole sonic logging following the French NF P 94-160-1 and the American D6760-16 standards. We are based in Belgium and also available in the neighbouring countries: the Netherlands, Luxembourg, and France.

Cross-hole sonic logging is also named the sonic core test or the CSL test.

Frequently asked questions

-

For a pile, how many reservation tubes are needed?

According to the French standard NF P 94-160-1, the required number of tubes is according to the pile diameter (D):

2 tubes for D ≤ 0.6 m

3 tubes for 0.6 < D ≤ 1.2 m

At least 4 tubes for D ≥ 1.2 m

-

What are the specifications of the reservation tubes?

-

Steel, not PVC

-

Nominal diameter 50 mm

-

Closed-ended at the bottom and temporarily plugged at the top

-

Protruding 0.2 to 1.0 m above concrete level

-

Generally made of several sections connected by watertight sleeves

Example: Sonitec ST50-1.5mm

-